Heat Tracing System

Electric heat tracing system

Electric heat tracing is a system used to maintain or raise the temperature of pipes and vessels. Trace heating takes the form of an electrical heating element run in physical contact along the length of a pipe. The pipe must then be covered with thermal insulation to retain heat losses from the pipe. Heat generated by the element then maintains the temperature of the pipe. Trace heating may be used to protect pipes from freezing, to maintain a constant flow temperature in hot water systems, or to maintain process temperatures for piping that must transport substances that solidify at ambient temperatures. Electric trace heating cables are an alternative to steam trace heating where steam is not available or unwanted.

Freeze Protection

Every pipe or vessel is subject to heat loss when its temperature is greater than ambient temperature. Thermal insulation reduces the rate of heat loss but does not eliminate it. Trace heating maintains the temperature above freezing by balancing heat lost with heat supplied. Normally, a thermostat is used to energise when it measures temperature falling below a set temperature value - usually between 3°C and 5°C and often referred to as the 'setpoint'. The thermostat will de-energise the trace heating when it measures temperature rising past another set temperature value - usually 2°C higher than the setpoint value.

Temperature Maintenance

Hot water service piping can also be traced, so that a circulating system is not needed to provide hot water at outlets. The combination of trace heating and the correct thermal insulation for the operating ambient temperature maintains a thermal balance where the heat output from the trace heating matches the heat loss from the pipe. Self-limiting or regulating heating tapes have been developed and are very successful in this application.

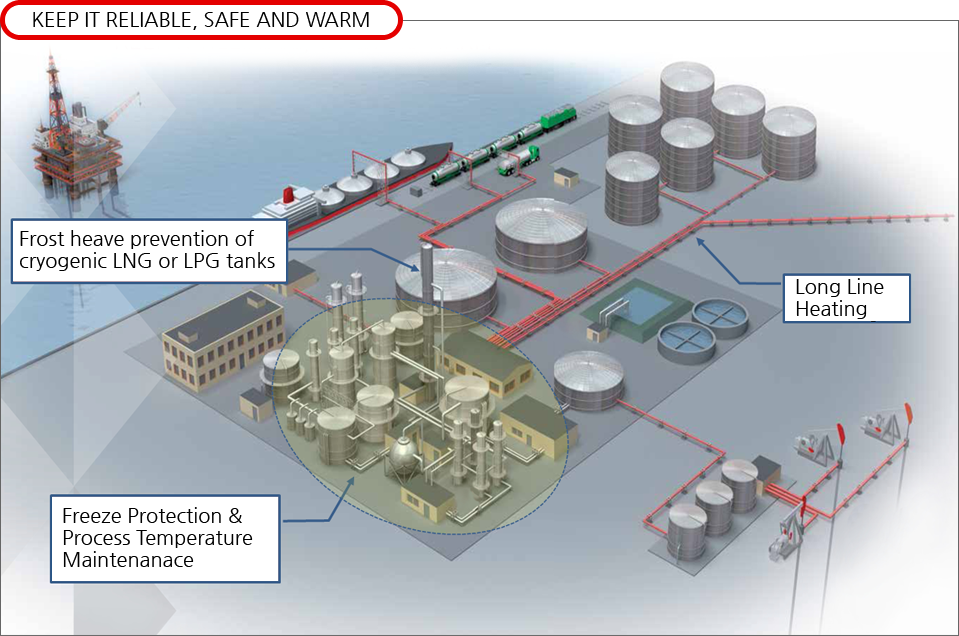

Longline Heating

Industrial longline heating is necessary to heat long pipelines, like transfer lines between processing plants or between storage or transportation facilities, for pipe freeze protection, condensation prevention, viscosity control, or temperature maintenance.

The complexity of this pipe heat trace system comes from the need for long electrical circuit lengths, usually with a single electrical power point.

Frost Heave Prevention

Frost Heave Prevention systems can prevent the ice buildup in the ground underneath cryogenic tanks.

Ice buildup can cause problems such as unwanted or uncontrolled movement or elevation of the tank.